Description of Lead-Acid Battery Recycling Plant

The battery recycling plant employs a proprietary mechanism process that effectively separates the lead and plastic components from lead-acid batteries. The lead produced by this process is of 97% purity. This eco-friendly method is a more sustainable alternative to traditional pollution-based processes, such as burning and chemical processing.

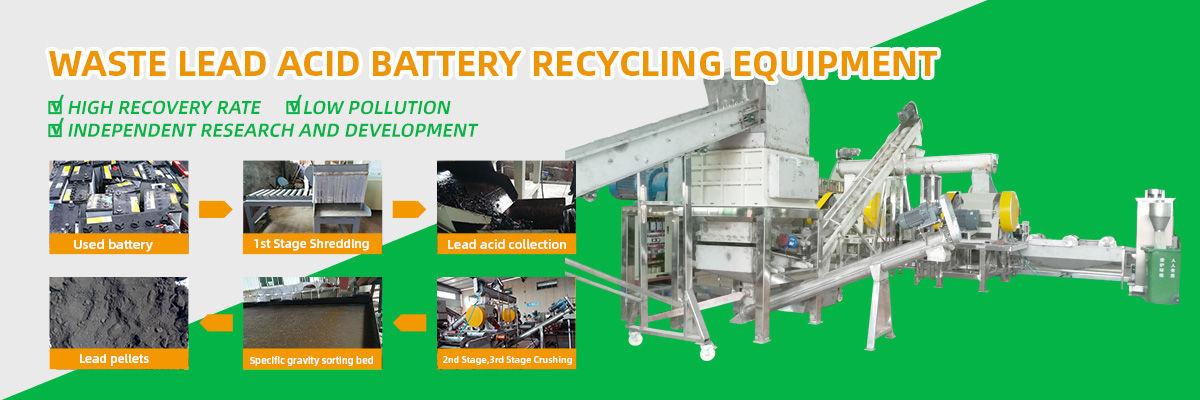

The battery recycling plant comprises a series of machinery and equipment, including a lead-acid battery cutter, shredder, vibration screen, conveyor, granulators, washing tank, hopper, screw conveyor, and gravity separation table (shaking/shaker table), which collectively facilitate the recycling process from the inlet of waste batteries to the production of recycled lead.

Our company has developed an innovative waste lead-acid battery recycling system that employs a range of cutting-edge technologies. The process begins with the breaking and separation of lead batteries, followed by the separation of acid, lead paste, lead grids, and plastic. The battery is fed into a shredder via a conveyor belt, then undergoes granulators and a water power sorting system. This allows for the separation of plastic and lead grids and paste based on their density. The electrolyte in the battery, or waste acid, is then derived and recycled in the waste acid treatment system.

Parameters of Lead-Acid Battery Recycling Plant

| ITEM | TECHNICAL STANDARDS |

| Capacity | 0.5-5 Tons per Hour |

| Overall Size |

25*5*7 m (Its depend on Capacity) |

| Lead Recovery Rate (Weight%) | 96% |

| Plastic Recovery Rate (Weight%) | 98% |

| Purity of Lead (%) | 99% |

|

Option |

|

|

1. Standard model machine body made of durable steel .stainless steel acceptable as optional choice. 2. OEM acceptable .entire machine could be made according to different size of batteries. 3. 12 months warranty .one complete set of wearing parts delivery with machine for free. 4. Battery shell cleaning and crush system and crush system available as option. |

|

Process Flow of Lead-Acid Battery Recycling Plant

Step 1.The battery conveyed by belt conveyor for Preliminary crushing(900×1050 4 shaft shredder),the crushed lead particles, plastic particles, and lead mud will be sorted in the first step by the vibrating screen at the bottom of the shredder, and a part of the lead mud will be separated.

Step 2.the particles after the first crusher conveyed to the second crusher for smaller particles by screw conveyor.

Step 3. After the second crushing, the particles will enter the washing tank, and the light plastic will be sorted out here. The heavy lead particles and heavy plastic will sink to the bottom of the tank and be transported to the separation equipment by the screw conveyor for sorting.

Step 4.Finally, the difference in specific gravity between plastic and lead particles is used to separate the two materials with a shaking table to obtain lead particles and plastic particles without impurities.Lead particles can be smelted through a smelting furnace to make lead ingots, while plastic particles can be used for secondary use.

Step5.In the process of crushing and sorting, the lead mud needs to be separated from water by a filter press, and then smelted together with lead particles to obtain lead ingots

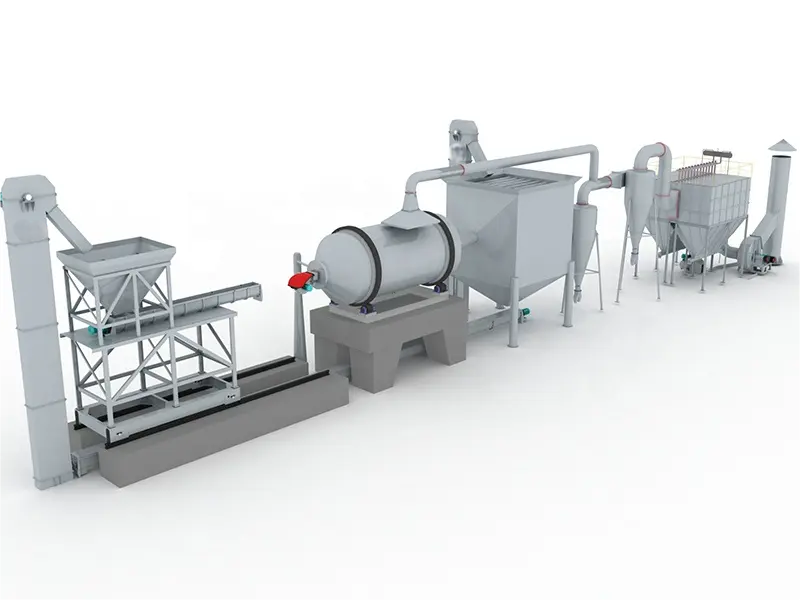

After you get the lead particles you can selling them to a Smelting company or you can build a melting plant by yourself ,we also supply the Advanced Rotary and Refining Furnaces,the following are relevant case pictures.

Related Equipment

Explore MINGXIN's range of complementary equipment for comprehensive battery recycling solutions.

Desulfurization,Purification, Crystallization System

This system is to desulfurize and purify the electrolyte and lead mud that flow out during the crushing and sorting process, so as to ensure that no secondary pollution will be caused during the entire lead-acid battery recycling process.

At present, customers can rotate whether they need to configure purification and crystallization systems according to their own cost budgets. There are currently two different crystallization methods in the crystallization system to produce two different crystalline sodium sulfide or ammonium sulfide. Of course a desulfurization system is necessary.

The Approximate Steps are as Follows:

A.The lead mud from the battery crushing unit is filtered into lead paste by the crushing filter press and then enters the desulfurization reaction tank for desulfurization reaction with sodium carbonate, and the filtrate after the filter press can be reused.

B.Lead paste desulfurization reaction uses desulfurization lead paste cleaning solution or tap water as the reaction medium, adds lead paste from crushing unit, prepares lead mud slurry, and puts into sodium carbonate for desulfurization reaction,After the reaction is completed, it enters a desulfurization filter press for solid-liquid separation to obtain desulfurization lead paste and sodium sulfate solution. The desulfurized lead paste is sent to the desulfurized lead paste processing unit after cleaning, and the cleaning liquid is used as the bottom water of the reaction medium for the desulfurizationof the lead paste.

C.The sodium sulfate solution is sent to the purification system. After the purification system, sodium hydroxide is added to adjust the pH value and the heavy metals are deposited by adding chemicals. After filtering out the heavy metal filter residues through the filter press, the filter residues are collected by the lower trolley and then transferred to the desulfurization lead paste processing unit, and the filtrate is recycled. Adjust the pH value to neutrality with sulfuric acid, send it to the purification filtrate storage tank, and wait to enter the MVR evaporation and crystallization system.

D.Sodium sulfate is obtained after being processed by the MVR evaporation drying packaging system, and the evaporated condensed water is returned to be recycled as lead paste cleaning water, and the sodium sulfate is packaged and sold.