Back ground of printed circuit board scrap|pcb recycling

The main components of the circuit board (PCB) are substrates and electronic components, and the main components are non-metallic components such as metals, oxides, organics, glass fibers, and epoxy resins. At present, it basically does not contain environmentally sensitive substances and has a certain recycling value.

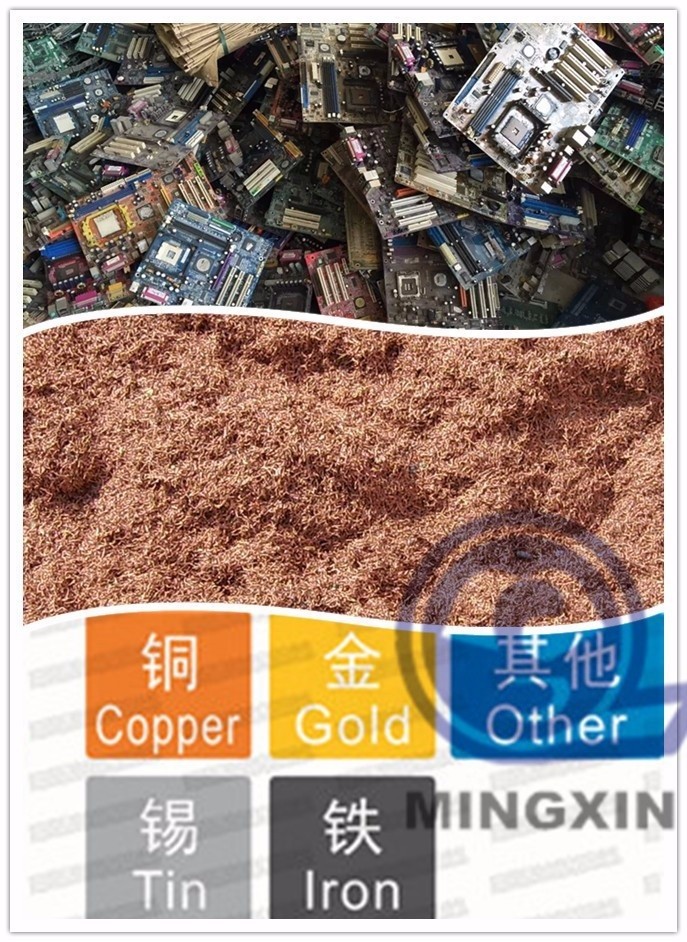

The metal grade in the circuit board(PCB) is equivalent to tens to hundreds of times that of ordinary minerals. The metal content is above 40%, mainly copper. In addition, there are gold, tin, nickel, lead, silicon and other metals, including rare metals, while the content of rich ore metals in nature is usually only 3-5%. In addition, the non-metallic slag of discarded circuit boards(PCB) can be used as construction raw materials. At the same time, solder and plastic on discarded circuit boards are also important resources that can be recycled. Therefore, the establishment of more and more circuit board(PCB) recycling plants provides a final destination for a large number of discarded circuit boards, and can better protect the environment and their own health.

Description of our printed circuit board scrap|pcb recycling machine

Our circuit boards recycling machine adopts advanced physical recycling process, which can help you obtain metal, resin powder and fiber powder from used printed circuit boards. Copper powder and resin fiber powder can be sold directly in the market, therefore, recycling pcbs can not only bring great economic value, but also protect the environment.

Applications of our printed circuit board scrap|pcb recycling machine

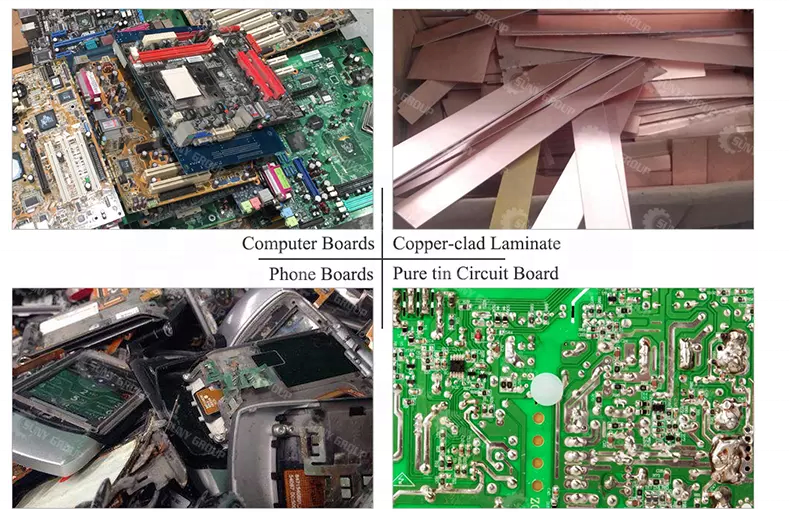

all kinds of pcb raw materials,such as

(a)Computer motherboards, Cell phone boards, Tv Boards,Freezer boards,air-conditioner boards,Radio Boards,Printer boards, overleft of pcb ,Coated copper plate/copper clad laminate.

(b).electronic components, such as capacitance, resistance, potentiometer, relay,etc.

Final output material of the pcb circuit boards recycling machine

Affter we process the circuit boards (pcb) we can obtain metal, resin powder and fiber powder from used printed circuit boards.In addition, the non-metallic slag of discarded circuit boards(PCB) can be used as construction raw materials.

The processing step of printed circuit board scrap|pcb recycling machine

Step 1: Electronic components dismantling

Usually, the first step of circuit board recycling is to separate the electronic components from the circuit boards by using PCB dismantling machine. Then you will get naked circuit mother boards, which will get further processing to get copper powder and resin powder.

Step 2: PCB boards shredding and crushing

Circuit board shredder is the very first machine to size reduce circuit board. Its infeed opening should be big enough to process tons of circuit board at the same time. During shearing and crushing of 2 rotors, circuit boards are broken down into irregular pieces. For the first shredding machine, we choose the double shaft shredder. After circuit board shredding, the particles are around 60mm by 60mm. Next, the second crushing machine is a granulator, resulting in 20mm particles. Then the shredded material is collected in a mesh box and processed further.

Step 3: Separate the metal and non-metal powder

The shredded PCB will be separated by the air separator and the electrostatic separator. Our PCB recycling machine adopts dry type and physical crushing, separation and dedusting methods, which can keep no pollution to the environment. And the high pressure electrostatic separation combined with air separation process, which can purify approximately 99% metal powder.

Features of our pcb circuit board recycling machine

A.High rate of metal recovery

B.Saving power,saving manpower

C.Electricity choose separation efficiency is as high as 99.9%, finished products can be directly put on the market.

D.No pollution, due to the pulse dust removal equipment.

E.High purity rate of end-pure copper as high as 97%.

F.PLC system makes it easier to control the whole line, the negative pressure feeding system prevents the dust from running out

Technical parameters our pcb circuit board recycling machine

Capacity:0.5-2t/h

Operators :3

Appearance size: 32311 X 9321 X 6350 mm

Equipment power: 310 kw or less

Power supply, three-phase ac 380 v / 50 hz, 200 kva.

The iron recovery rate (weight %) : 99%

Copper recovery rate (weight %) : 95%

The recovery rate of epoxy resin (weight %) : 95%

Noise, dust leakage and emissions in line with national standards and requirements.

Venue: plant height more than 7 meters;Gate width is greater than 4 m height is greater than 5 meters;Bearing more than 10 tons of

Equipment, appearance and color: according to the Client`s standard.

We are experts in the field of solid waste recycling especially metal recycling. We can provide a complete set of solutions, including waste cable recycling, waste circuit board recycling, metal and non-metal crushing and sorting, mixed plastic recycling, etc. If you have any need of our machine, feel free to contact Mingxin equipment.