PRODUCT DESCRIPTION

Solar PV recycling (photovoltaic) is an up and coming waste stream generated in both consumer and commercial fields of use. While demand may not be terribly high at the moment, there are many early-era solar power systems or solar PV systems that will soon be reaching their end of life cycle. MINGXIN stands ready to deliver industry leading end of life management solutions for commercial and consumer solar energy systems.

The rest of the components in a solar panel consist of good quality glass, aluminium frames, polymers,silicon, copper and silver paste (used for the printed conductors on each cell), all of which (≥95%), can be successfully recycled.

RECYCLING PROCESSING

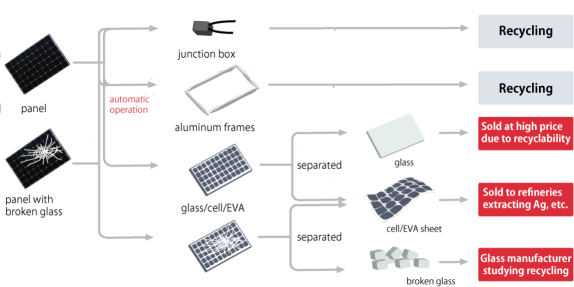

1. Disassembly Process

Initial disassembly:

The junction box of the PV panel as well as the surrounding aluminum bezel are removed from the solar panel using an automated framing machine. This step makes the subsequent handling process more efficient and reduces the need for manual handling.

Softening Process:

After the frames are removed, the PV panels are transferred to a softening oven. Inside the oven, heated tubes bake the glass panels uniformly and the panels are softened at high temperatures to dissolve the EVA film. This process facilitates the subsequent peeling of the glass from the backsheet.

Glass Separation:

After the softening process, the PV panels are transported to the head section of the machine. At the headstock location, there are two rollers, and the PV glass panels are fed into the center of the rollers and squeezed to move forward.

At the same time, the glass panels are mechanically broken and separated by means of a knife (left-right reciprocating motion). The separated glass portion flows downwards at the exit and is collected and processed manually, while the glass panes are sent out above and again collected manually.

This automated dismantling and treatment process ensures efficient recycling of the PV panels, while reducing manual intervention and improving overall treatment efficiency and safety.

2. Crushing And Separation

Shredder:

The material enters into the shredder through the conveyor, the two shafts are equipped with staggered blades, the two knife shafts in the process of rotating in opposite directions to achieve crushing through the shear of the knife blade as well as the tear of the knife teeth, crushing the raw material into smaller pieces, and sending it to the next shredder through the conveying device. The output size of the shredder is 3-4 centimeters.

Granulator:

Through the conveyor will be shredded materials into the crusher, the crusher is composed of blades and through the blade disk, through the rapid rotation of the blade hit the broken material will be further broken up and crushed, to facilitate the subsequent vibration screening process. Crushed material through the negative pressure air system into the next process. The pulverizer is equipped with sieve mesh aperture of 2.8 mm.

Vibratory Screen:

The heavier material collected by the analyzer falls into the inlet of the grading screen, and the material with the required granularity through screening enters the specific gravity sorter for the next step, and the granularity not meeting the requirements is sent to the next process of grinding machine for further grinding. Grading screen is a layer of screen, screen aperture of 10 mesh-20 mesh.

Hammer Mill:

The materials not meeting the requirements of granularity separated by the grading sieve are further ground by the grinder and flow into the collector through the induced draft fan for subsequent processing.

Gravity Separator:

The materials meeting the requirements of granularity after grinding by the mill and screening by the grading sieve enter the specific gravity sorting machine for sorting and processing again respectively, of which the front outlet is the heavier metal powder, and the rear outlet is the lighter mixed powder of metal and plastic.

Electrostatic Sorter:

The mixture sorted out at the back end of the specific gravity sorting machine is fed into the high voltage electrostatic sorting machine through the spiral reamer and bucket elevator, in which the resin powder and copper powder are subjected to the final sorting process to get the resin powder and copper powder.

Pulse Dust Collector:

The raised dust and ultra-fine dust produced in the operation of the whole set of equipment will be collected and discharged under negative pressure for treatment.

FINAL MATERIAL