Description

The MX-200 single-phase copper granulator machine is specially designed for customers who require a small-capacity copper wire granulator. It can achieve a high separation rate of 99.9% and run well on a single-phase power supply, which is suitable for customers who have limitations in electricity. This machine is manufactured using CNC machining technology, which can develop precision and accuracy of the machine during the manufacturing process. And this ensures the working efficiency and performance of machine, which can let you sell copper granules at a higher price.

Specification

- ·Capacity: 30-60 Kgs. per hour

- ·Dimensions: 560x805x1550 mm

- ·Weight: 300 Kgs.

- ·Motor: 4.5 Kw

- ·Application: 0.2-20 mm available

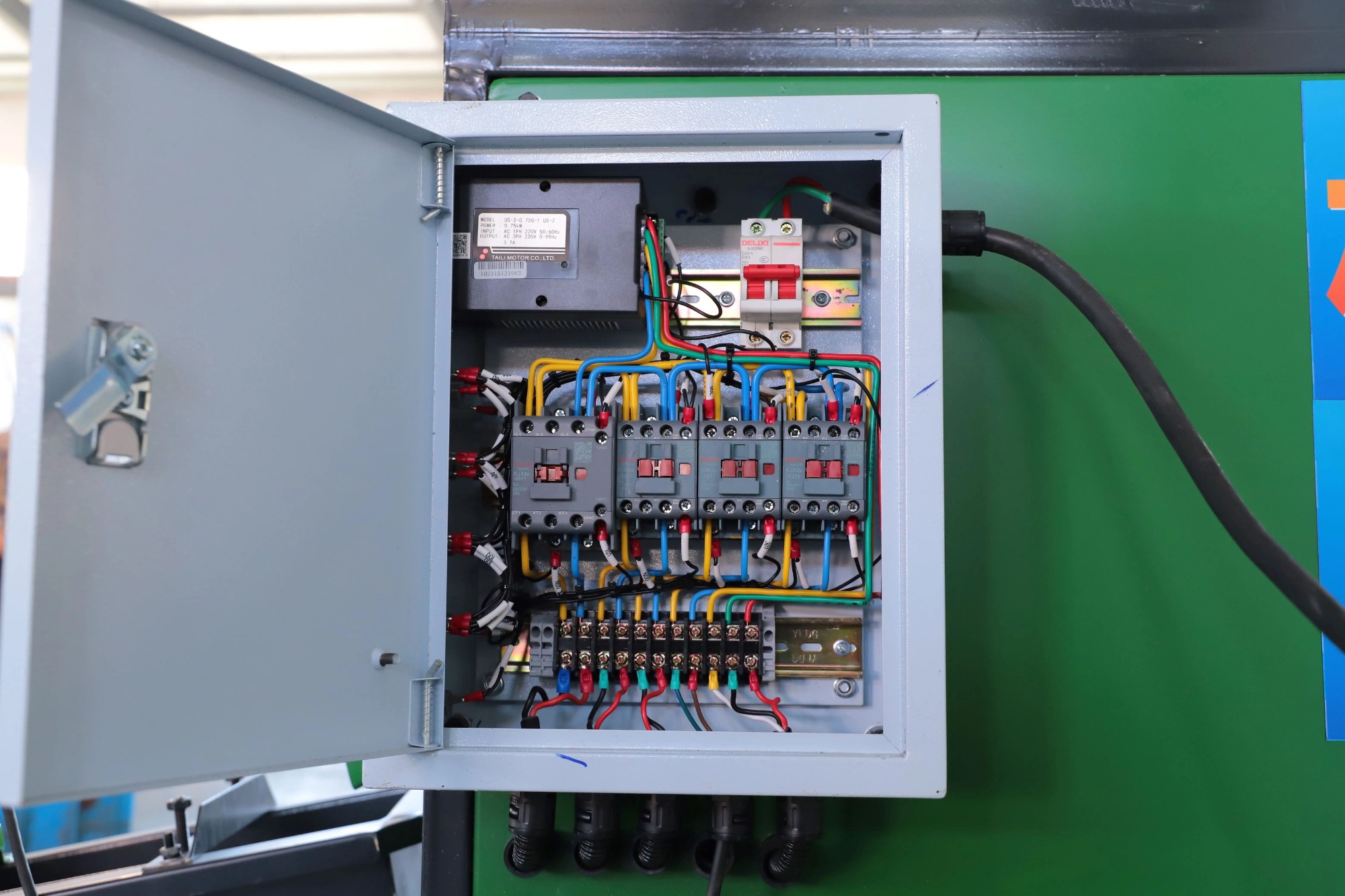

Machine Details

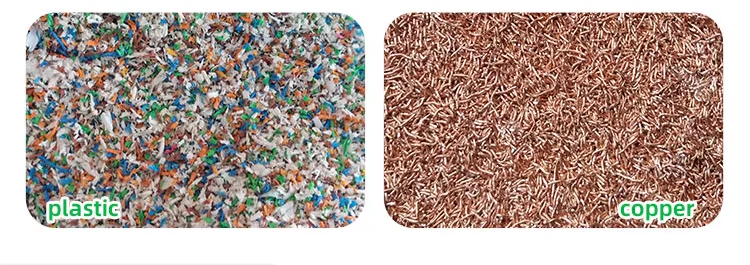

Final Product

The copper wires granulators process waste electirc wire and cable into copper and plastic granule. Copper is separated from the plastic, separation efficiency can be 99%. For the copper granule, it can be sold directly or go to further refining.

Electric cable shredding plant can be implemented with optional equipment to increase their production capacity when customers needs increase.

Package and Shipping