DESCRIPTION

The MX Series of granulators are suitable for processing of a wide range of plastics, producing high quality granulate, including blow-moulded materials such as PET bottles, PE/PP bottles, canisters and buckets. In addition the MX series can be specified to shred resistant materials like thick wall pipes.

Either as a stand-alone solution or as stage of a two part process (downstream of a primary shredder) the MX is a straightforward and economical size reduction solution.The various sizes and different versions make it possible to match the MX to your specific material and throughput requirements.

WORKING PRINCIPLE

At the core of our plastic granulator machine is an open rotor mounted with heavy-duty Blade in either a double-scissor cut or V-shape array based on your requirements. As the rotor is spun at high speeds, the rotor blade come in contact with stationary blades that are mounted within the cutting chamber. The material is continuously cut until they are small enough to pass through a screen filter.

Generally speaking, our filter screen are between 10mm to 100mm but can be customized according to your requirements.

Our standard plastic granulator houses 12 rotor and 3 stationary blades. All Blades use only ultra durable D2 (equivalent to SDK11) high-carbon, high-chromium steel which ensures the longest usage times before requiring sharpening. All blades are easily adjustable with hydraulic assisted access to the cutting chamber.

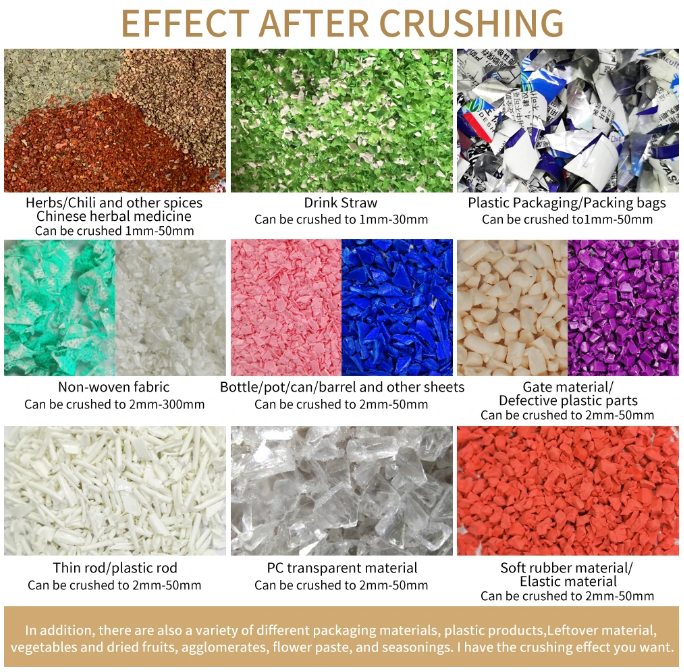

APPLICATION

SPECIFICATION

|

Model

|

MX-650

|

MX-900

|

MX-1200

|

|

Voltage(V)

|

380V/50HZ/3Phase (Can be customized)

|

||

|

Width of Crusher Chamber (MM)

|

650

|

900

|

1200

|

|

Rotational Diameter (MM)

|

500

|

420

|

420

|

|

Number of Rotary Blades

|

6

|

9 | 12 |

|

Number of Fixed Blades

|

4

|

6 | 8 |

|

Feed Port Size (MM)

|

650*530

|

900*650

|

1200*650

|

|

Spindle Diameter (MM)

|

150

|

150

|

150

|

|

Motor Power (KW)

|

22+1.5

|

30/45+1.5

|

75+1.5

|

|

Screen Aperture (MM)

|

14 (Customized)

|

||

|

Capacity (KG/H)

|

400-500

|

800-1200

|

1500

|

|

Dimensions (MM)

|

1800*1450*1500

|

1915*1700*2712

|

2200*2150*4110

|