Description

Gold Shaking Table is fundamentally low-volume machines utilized as the last step in the gold mining process. The shaking table is a thin film, shear stream process hardware, that isolates pieces grains of its nourish material in view of the particular in their particular gravity, size, and shape. Mineral-rich particles, from light to large and fine to coarse will be arranged by net effective weight.

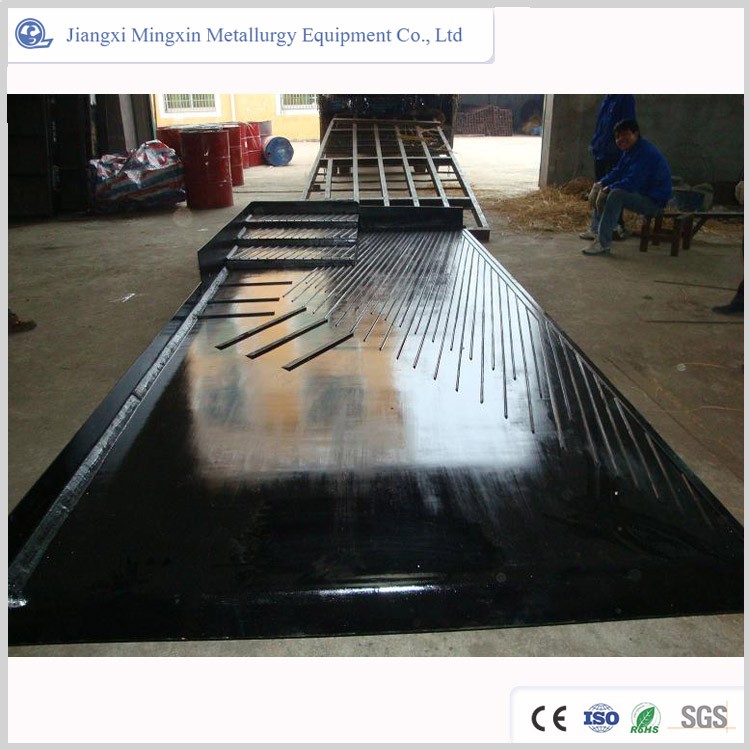

It is a gravity wet process mine machinery, the table deck is made of fiberglass reinforced with a wearable corundum surface. The mining shaker table is composed of three parts: the table head, the table deck, bearing and adjusting gradient.

Shaking table widely used to separate gold, tin, tungsten, chromite, silver, diamond, zircon, tantalum-niobium, lead, zinc, copper, other rare metal and noble metal ores.

Working Principle

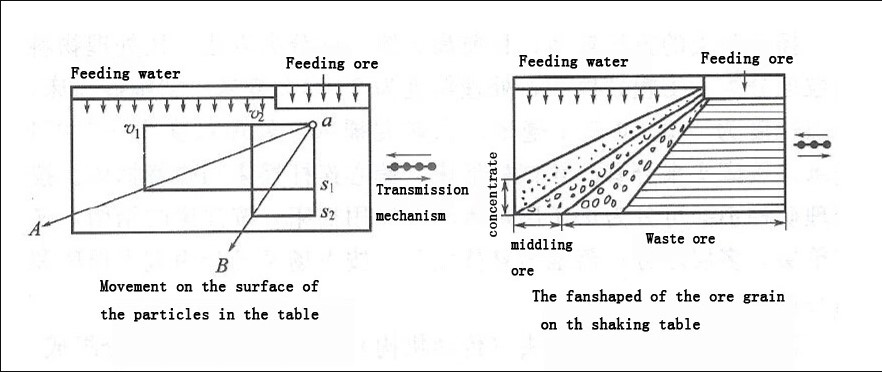

The working principle of the Shaking Table is separates the heavy material from light material by using their different proportion & specific gravity, under the effect of gravity, the minerals will divide into the ore concentrate, the middling and the tailing.

The prominent advantage of the ore shaking table is precise separation. The enrichment ratio of concentrate is very good, up to 95% high recovery ratio for kinds of heavy minerals, when dealing with low-grade tungsten ore and tin ore, the enrichment ratio could reach about 300 times.

At the final pounded or ground mineral material runs as feed blended with water to frame a mash (mud) and sustained as the slurry of a normal around 20– 25% of solids by weight onto the most top purpose of the table deck. The gold table’s deck has an equal motion along with its fundamental hub that is given utilizing a vibrator or a volatile head movement.

The table surface is made and fitted with a few narrow strips called riffles or channels, frequently made with of yellow pine that lead to back in time, low-thickness polythene or aluminum surfacing. Shaking tables and other thin-film isolating plants recuperate finely separated gold under terms of subcritical laminar and supercritical laminar administrations of the stream, which may happen just where there is a thin profundity of liquid.

A gold shaking table’s riffles decrease downwards in rising toward the path the gold and all heavy material, valuable metals concentrate release end of the table. This encourages the simplicity with which mineral particles can move transversal to the table’s pivot or shaker-line, subsequently helping segregation over the entire table length. Riffle statures and pattern diagrams are chosen in view of the crave and required functioning as anticipated.

Specification

|

Model |

6S-7.6 |

6S -4.08 |

6S -1.95 |

6S -0.5 |

|||

|

Deck Type |

Coarse Ore Deck |

Fine Sand Deck |

Slime/Slurry Deck |

Three Different Kinds Of Decks Are Available |

|||

|

Beneficiation Area (㎡) |

7.6 |

7.6 |

7.6 |

4.08 |

1.95 |

0.5 |

|

|

Deck Size |

Length (mm) |

4500 |

4500 |

4500 |

3000 |

2100 |

1100 |

|

Transmission Width (mm) |

1850 |

1850 |

1850 |

1320 |

1050 |

500 |

|

|

Concentrate Width (mm) |

1550 |

1550 |

1550 |

1100 |

850 |

430 |

|

|

Max. Feeding Size (mm) |

2 |

0.5 |

0.15 |

Sand -2 Slime -0.1 |

Sand -2 Slime -0.074 |

Sand -2 Slime -0.074 |

|

|

Capacity ( T/ Hour) |

1-1.8 |

0.5-1 |

0.3-0.5 |

0.4-1.5 |

0.3-0.8 |

0.05-0.2 |

|

|

Feeding Density (%) |

25-30 |

20-25 |

15-25 |

10-30 |

|||

|

Stroke (mm) |

16-22 |

11-16 |

8-16 |

6-30 |

12-28 |

9-17 |

|

|

Frequency (r/min) |

45-48 |

48-53 |

50-57 |

210-320 |

250-450 |

280-460 |

|

|

Water Consumption |

80-150 T/Day |

30-60 T/Day |

10-17 T/Day |

0.3-1.5 T/Hour |

0.2-1 T/Hour |

0.1-0.5 T/Hour |

|

|

Transverse Slope of Deck |

2°30-4°30 |

1°30-3°30 |

1°-2° |

0-10° |

0-8° |

0-10° |

|

|

Longitudinal Slope of Deck |

1.4 |

0.92 |

/ |

/ |

/ |

/ |

|

|

Groove Shape of Deck |

Rectangular |

Saw-tooth |

Triangle |

Rectangular/Saw-tooth/Triangle Available |

|||

|

Motor Power (kw) |

1.1 |

1.1 |

1.1 |

1.1 |

1.1 |

0.55 |

|