Description

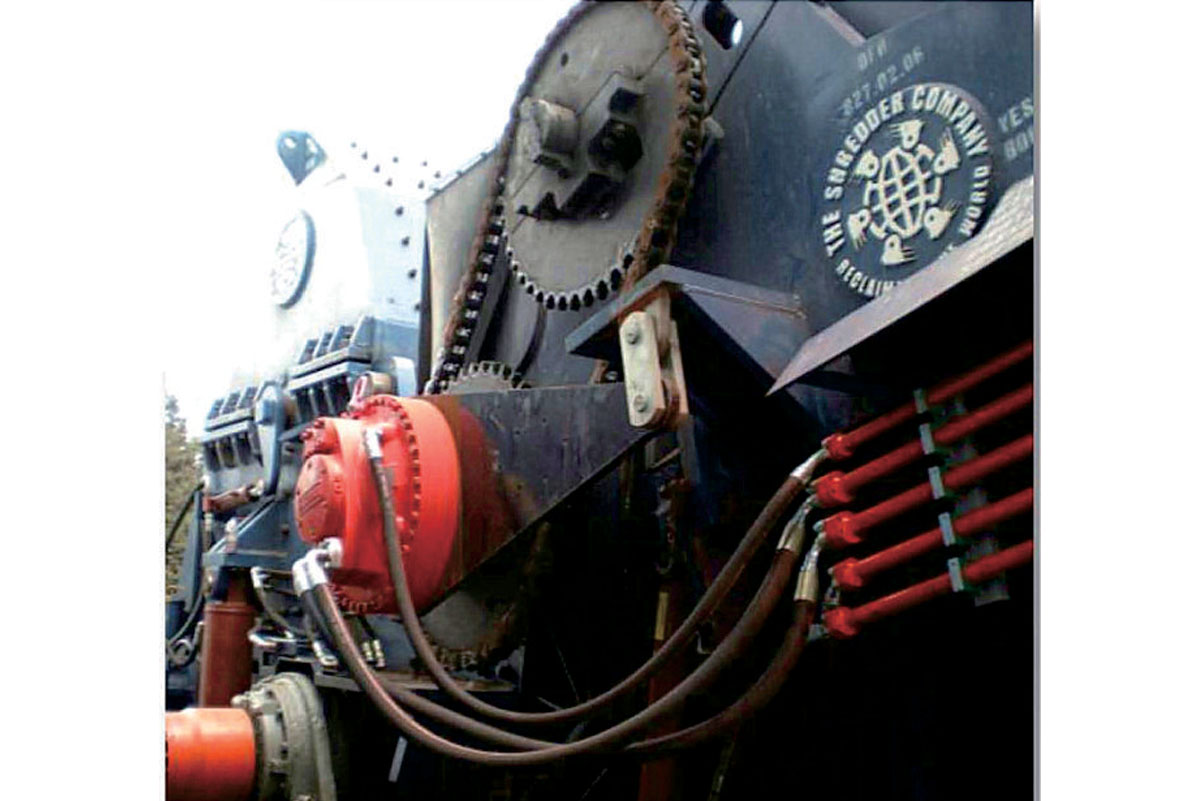

This waste steel crushing line is suitable for crushing waste light steel thin material, such as waste car body (removing engine, gearbox, tyre, etc.); tinplate class (colour steel tile, iron drum, can, etc.); household appliance products (removing motor, compressor, shaft, etc.); bicycle, truck fence and similar waste; cans (paint drum, oil drum, chemical drum, etc.); other waste steel (such as the density less than 0.6 of the package block, the thickness of ≤ 6mm thickness, steel plates, steel profiles, steel structural parts), etc.

It has the characteristics of reasonable design, reliable performance, high recovery rate of finished products, high automation procedure, safety and environmental protection, and can remove the coating film and impurities on the surface of scrap steel and improve the bulk density of finished products, etc. When the steel mill re-melts the products, it has the features of low energy consumption, high output and obvious comprehensive benefits. It can be widely applied to scrap recycling companies, steel mills and other industries.

Working Principle

Scrap steel crusher consists of frame, liner, screen, rotor, hammerhead, universal shaft, electric motor, electric control system, electric motor drives the rotor and hammerhead for high-speed circular motion, the bottom of the configuration of crushing screen, side configuration of the liner, the material from the inlet into the crushing chamber, the first by the high-speed rotation of the hammerhead, followed by the liner rebound to the hammer, so that the material in the crushing chamber back and forth to be hit and collide with each other during the movement to reach the size of the screen and discharged from the bottom discharge port of the crusher. In this way, the materials are hit back and forth in the crushing chamber and collide with each other in the process of movement, and then discharged from the discharge port at the bottom of the crusher after reaching the size of the screen hole.

Specification

Model

Input Size(mm)

Power

(KW)

Capacity

(t/h)

MX-200

800

200

1-5

MX-400

1200

400

5-10

MX-750

2000

750

15-20

MX-900

900

20-30

MX-1200

2600

1200

25-40

MX-1600

1600

40-50

MX-2000

2000

50-60

MX-2500

2500

60-80

MX-3000

2800

3000

80-100

MX-4500

4500

100-150